Semi-open Water Pump Magnetic Rotor

Combining the advantages of open water pump rotors and closed water pump rotors, it can meet the performance requirements of water pumps in most cases.

订制热线:0755 - 25989963

产品信息

Magnet: D12.4* total height 46.5mm, blade dia: 24mm

OD 4 poles, surface magnetism>1600Gs

FIRST,

The impeller of the magnetic rotor of the water pump has three types: open type, semi-open type and closed type.

Open impeller: no cover on both sides;

Semi-open: only one side cover

Closed type: there are covers on both sides;

Closed impeller: Less leakage and high efficiency, so it is the most widely used.

When there are many impurities in the water, an open or semi-open impeller can

be selected, so that it is not easy to get stuck.

SECOND,

The role of the magnetic rotor in the motor is to convert the mechanical energy

of the prime mover into the kinetic energy and pressure energy of the fluid.

THIRD,

Plastic options: POM, PA, PPS, PPE/PPO, POK, etc.

FOURTH,

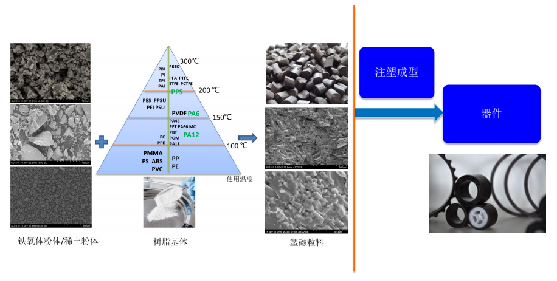

Injection molding magnetism: It is a kind of mixing thermoplastic resin (PA12,

PA11, PPS, etc.) and magnetic powder (ferrite, NdFeB, SmFeN, etc.) to the same as

ordinary plastics, and can produce various magnetic products with complex shapes

through injection molding process, often including injection molding ferrite,

injection molding NdFeB, injection molding SmFeN, etc.

FIFTH,

Compared with traditional craft advantages:

•Small specific gravity and light weight;

• Simple structure and low cost;

•Various and adjustable magnetic properties, various choices of

plastic substrates;

•Flexible device shape design, free orientation of magnetic poles;

• not easy to break, not easy to produce gaps;

• One-piece molding: high-speed operation does not fall off;

• High dimensional accuracy and small magnetic pole difference;

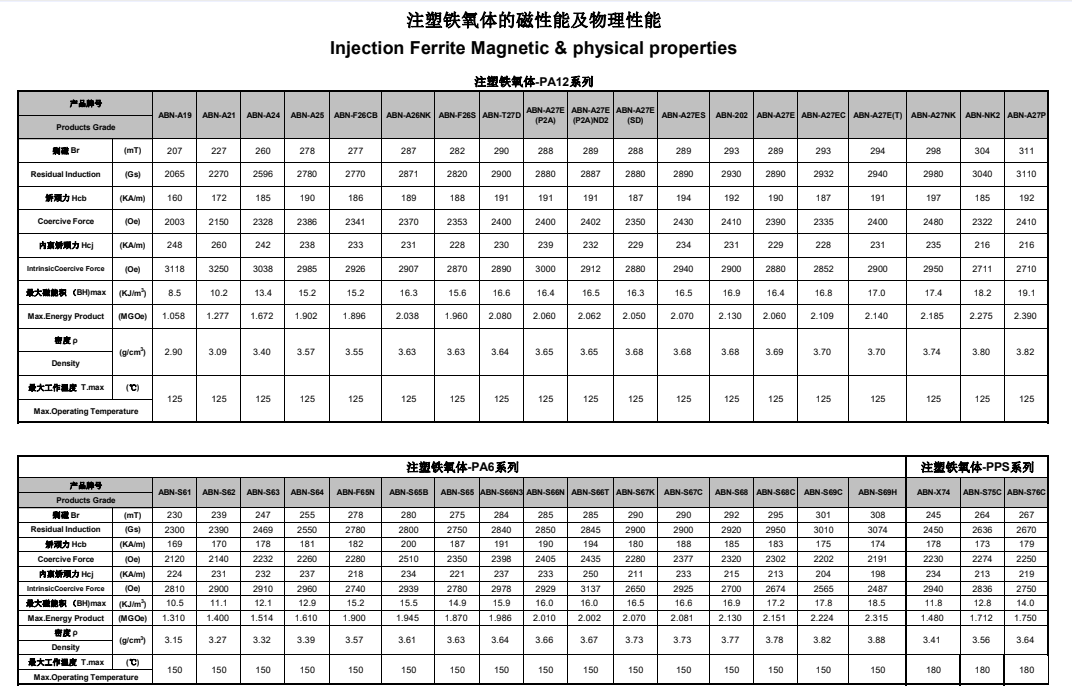

•Maximum working high temperature: the adhesive is PA12, and the

temperature resistance is 125°C;

The temperature resistance of PA6 as the adhesive is 150°C, and the

temperature resistance of PPS as the adhesive is 180°C.

SIXTH,

Advantages compared to similar products:

• High magnetic performance, more cost-effective;

• Better stability;

• High utilization rate of secondary recycled materials, reducing costs;

• Process diversification;

•Complete supporting technical services to provide overall solutions.

SEVENTH,

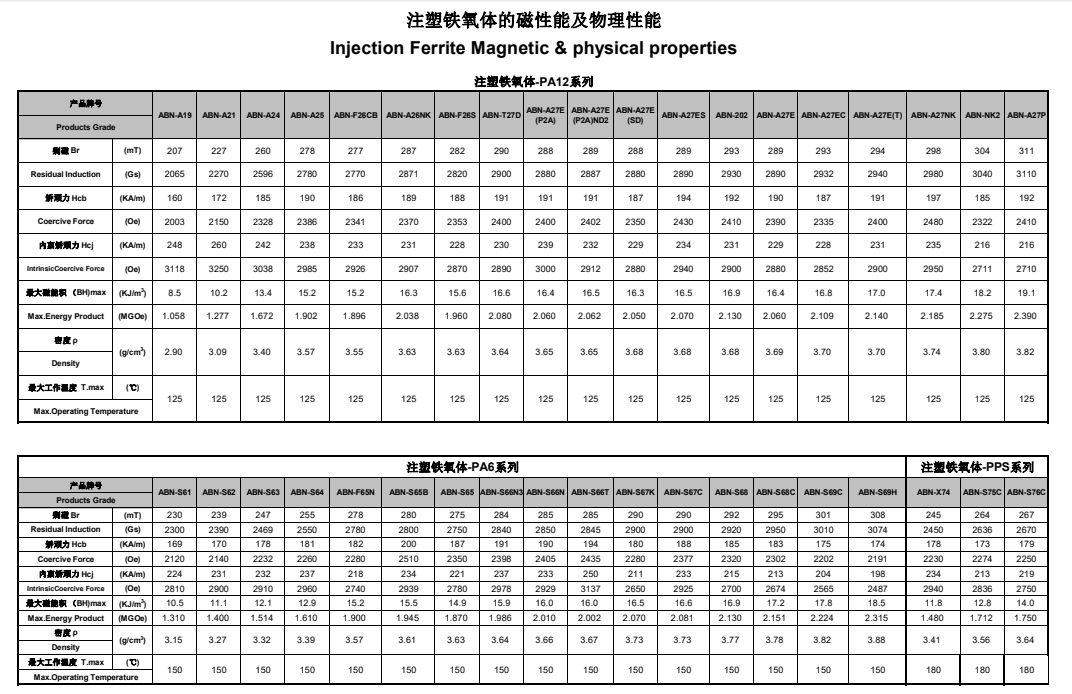

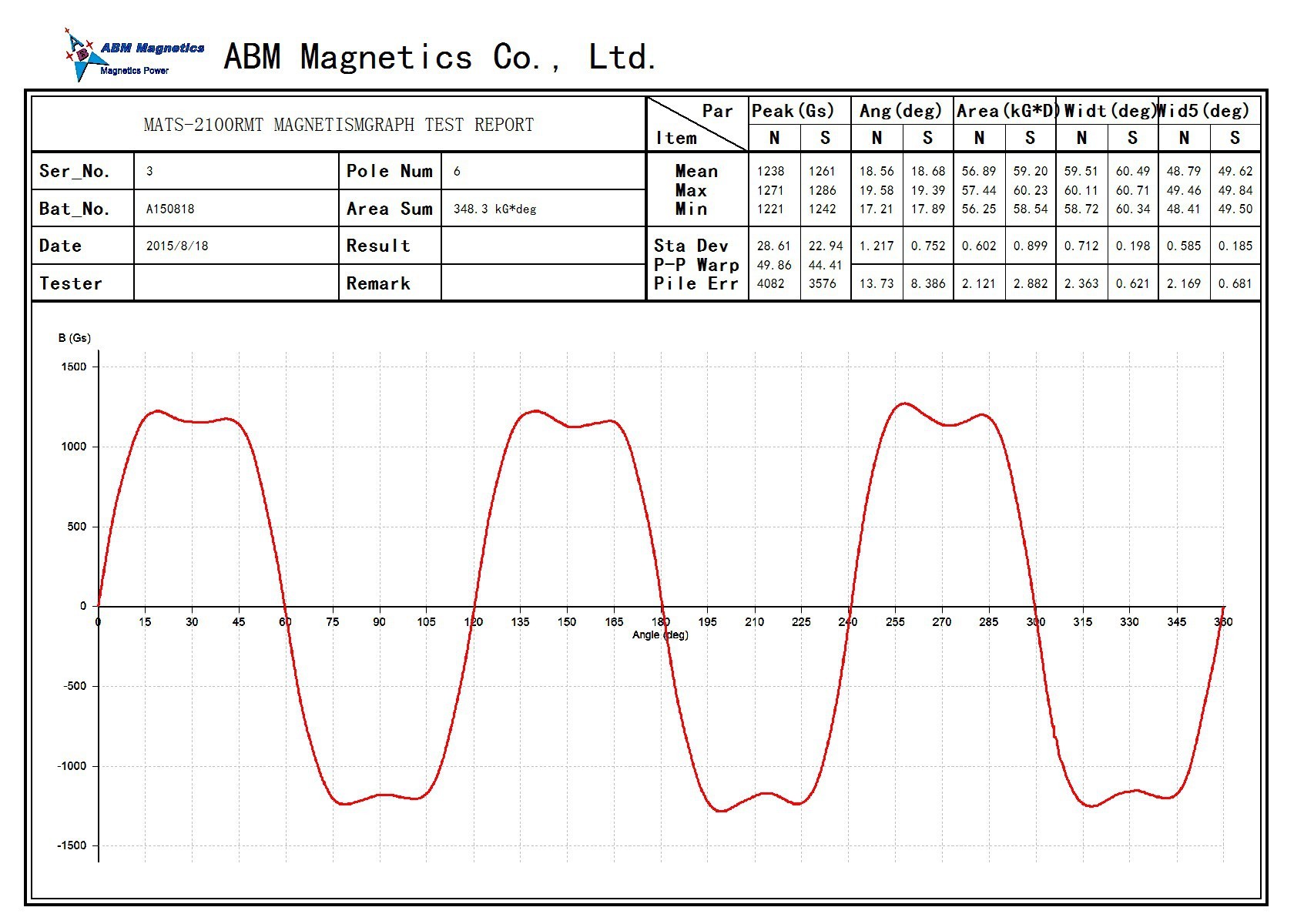

Injection ferrite magnetic performance table:

EIGHTH,

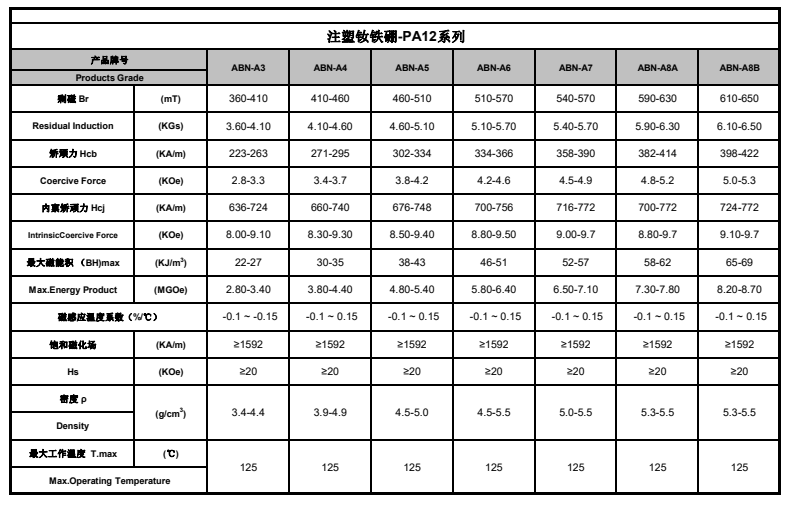

Injection NdFeB magnetic performance table:

NINTH,

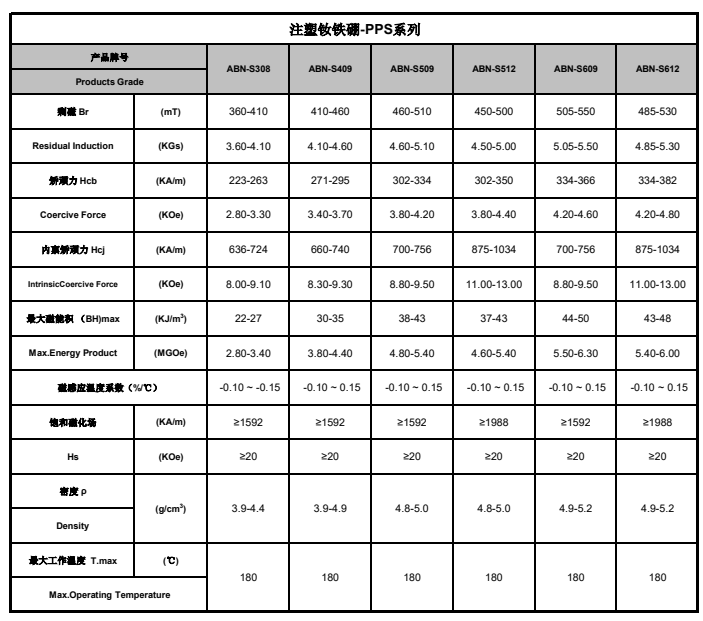

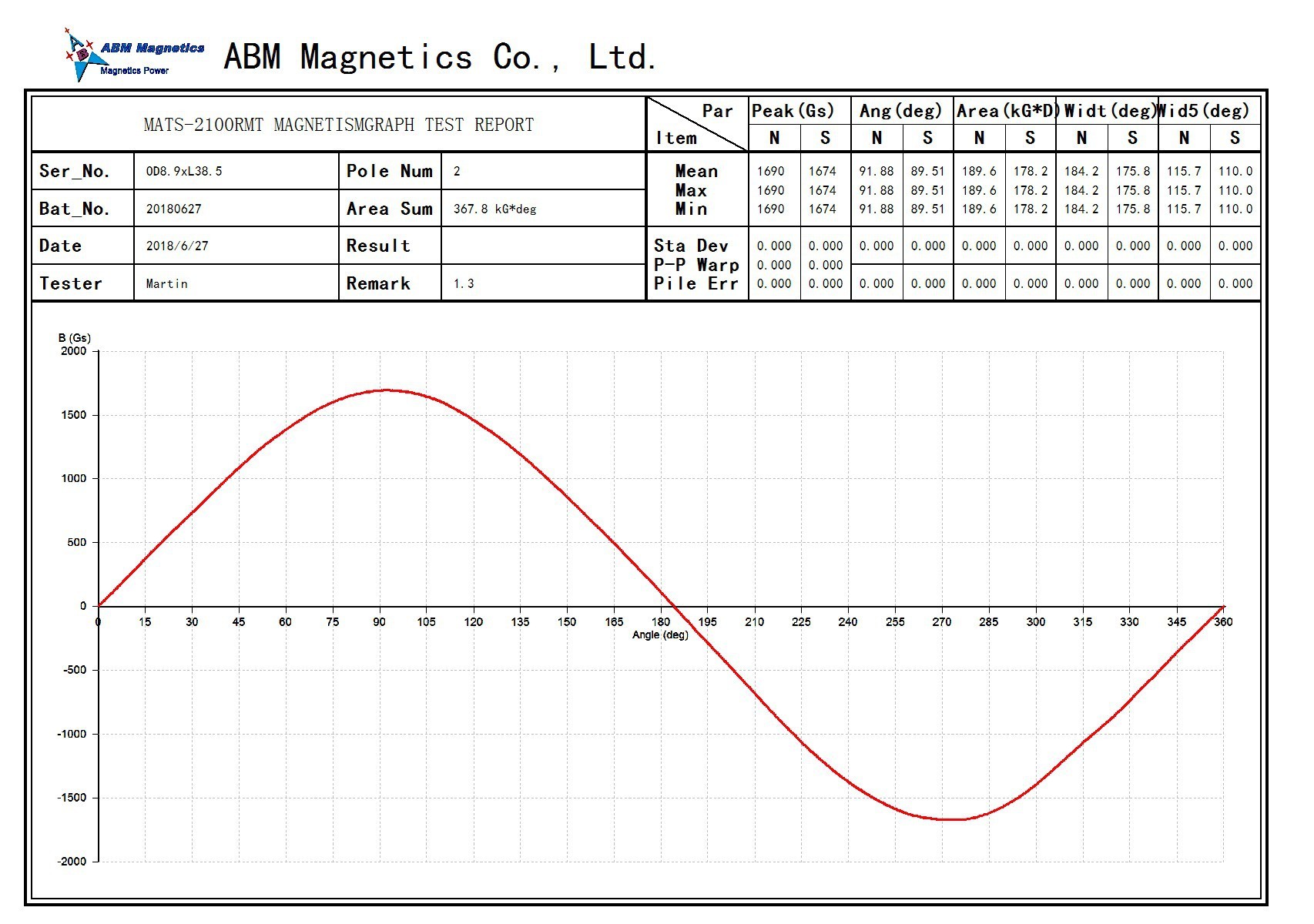

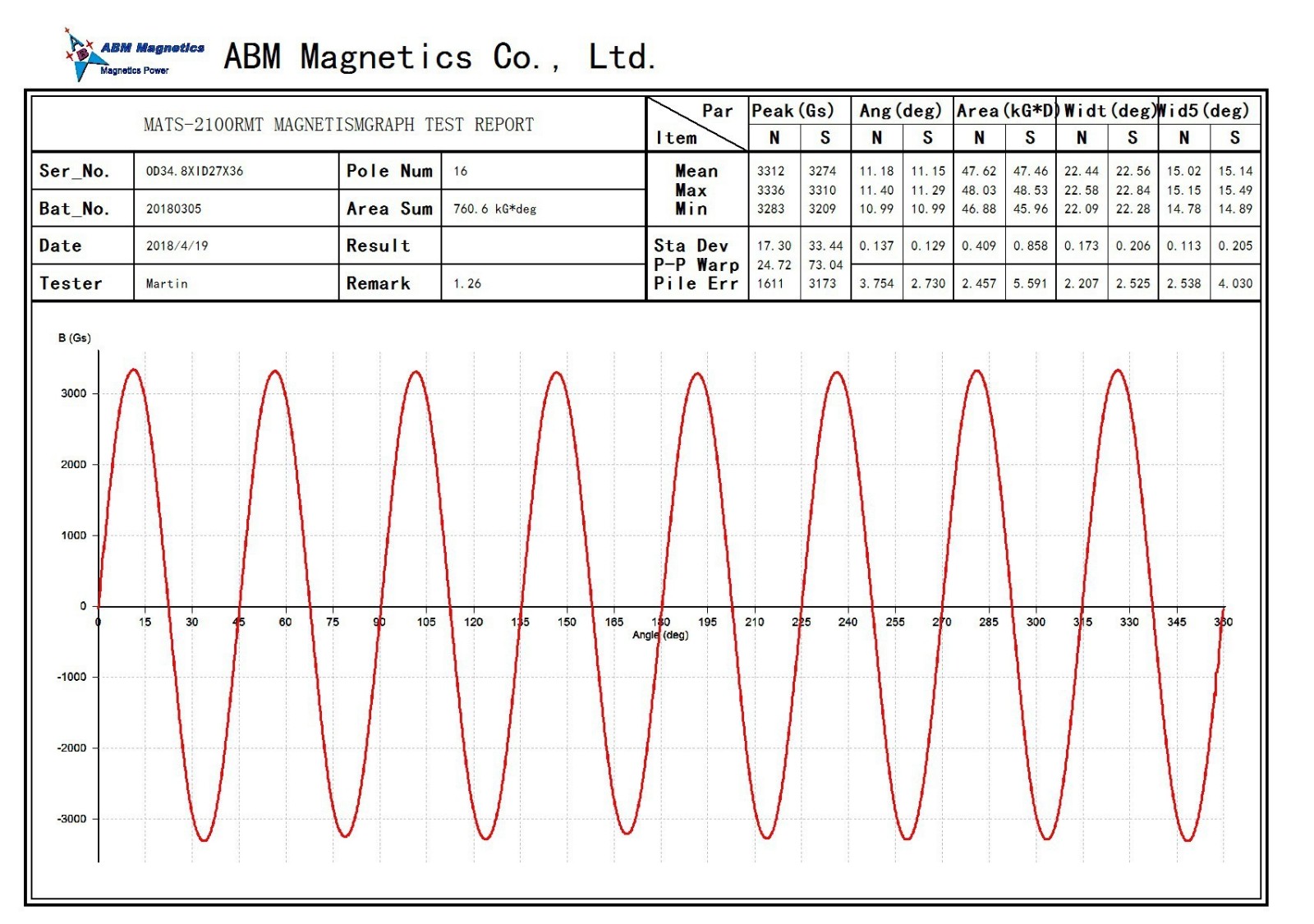

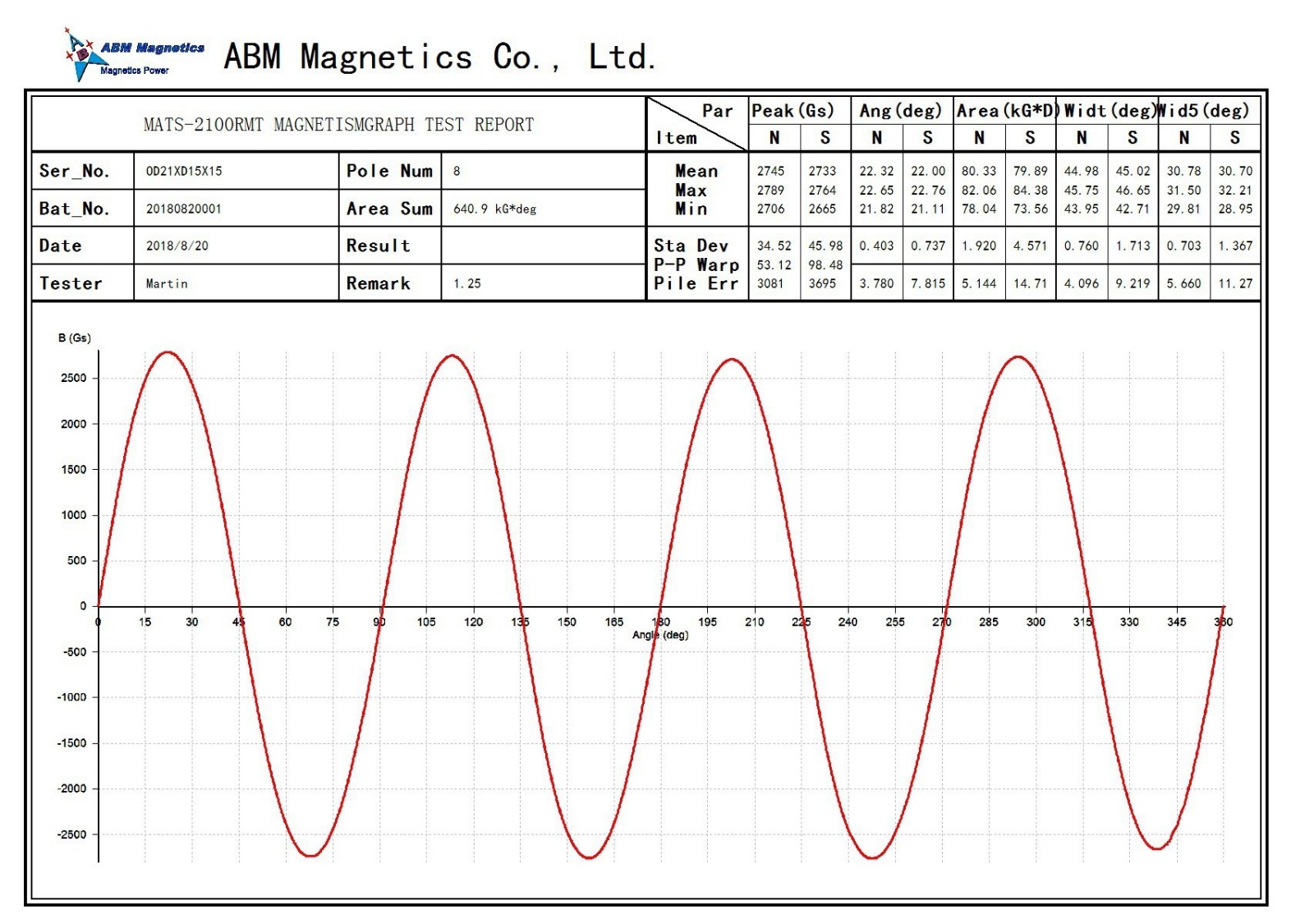

Waveforms can be customized as required:

Saddle Wave(6 Poles):

Sin Wave(2 Poles):

Sin Wave(16 Poles):

Sin Wave(8 Poles):

TENTH,

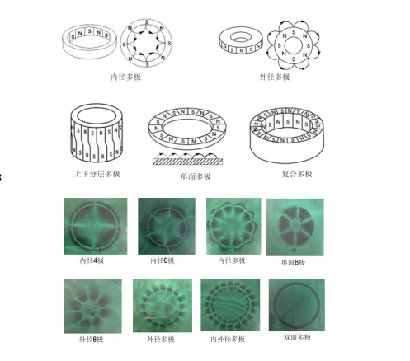

Magnetization method:

ELEVENTH,

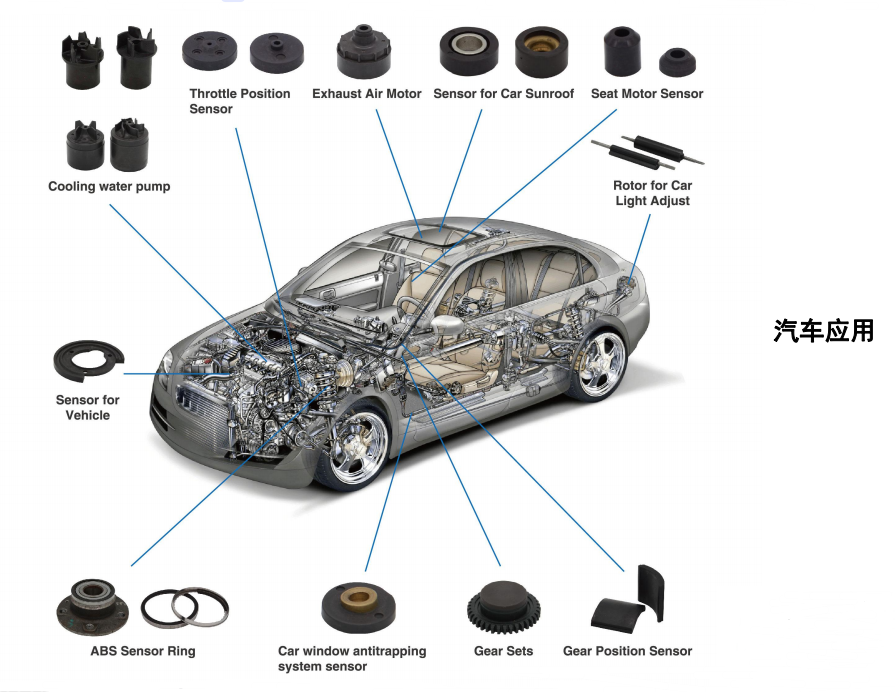

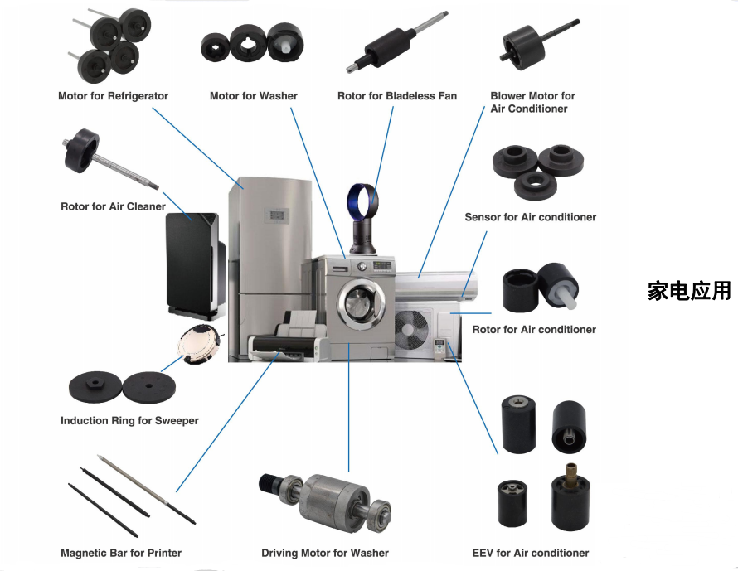

Application of injection molding magnets: Mainly used in automotive

applications, motor (household appliances/industrial) automation

equipment, water pumps, sensors, permanent magnet DC motors,

DC fans, inverter air conditioner motors, instrument motors, etc.

Household appliances:

Car Parts