Halbach Assembly Magnet

Halbach array magnets use different magnet arrangements to concentrate the magnetic force on a certain side or a certain part.

订制热线:0755 - 25989963

产品信息

At present, the surface magnetism of our Halbeck magnet array assembly can reach 17000Gs, which can be customized according to customer needs.

FIRST,

Halbach array

Halbach Array (Halbach permanent magnet) is a magnet structure. In 1979,

American scholar Klaus Halbach discovered this special permanent magnet

structure when he was doing electron acceleration experiments and gradually

improved it. Finally, the so-called "Halbach" magnet was formed. It is an

approximate ideal structure in engineering. It uses the arrangement of special

magnet units to enhance the field strength in a unit direction.

This kind of array is completely composed of rare earth permanent magnet

materials. By arranging permanent magnets with different magnetization

directions according to certain rules, the magnetic force lines can be gathered

on one side of the magnet steel, and the magnetic force lines can be weakened

on the other side, so as to obtain an ideal unilateral magnetic field. This is of

great significance in engineering, and the Halbach array has excellent magnetic

field distribution characteristics.

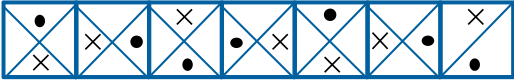

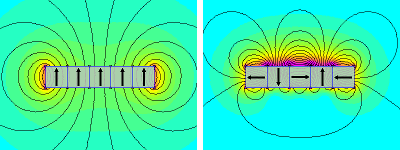

On the left is a single magnet with north poles all up and the strength of the

magnetic field can be seen from the colors at the bottom and top of the magnet.

On the right is a Halbach array with a high magnetic field at the top of the

magnet and a relatively weaker bottom. (Under the same volume, the strong side

surface magnetic field strength of the Halbach array magnet group is about √2

times (ie 1.4 times) that of the traditional single magnet, especially when the

thickness of the magnet magnetization direction is 4-16mm).

SECOND,

Form and Application of Halbach Array

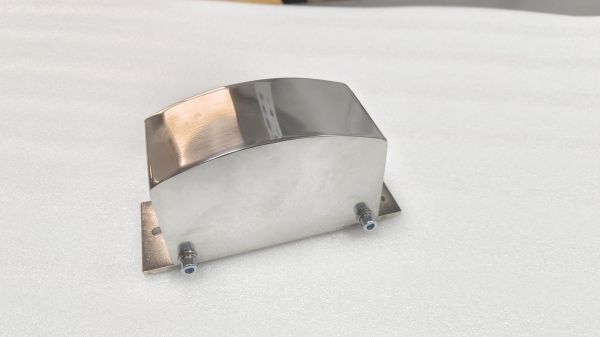

LINEAR ARRAY

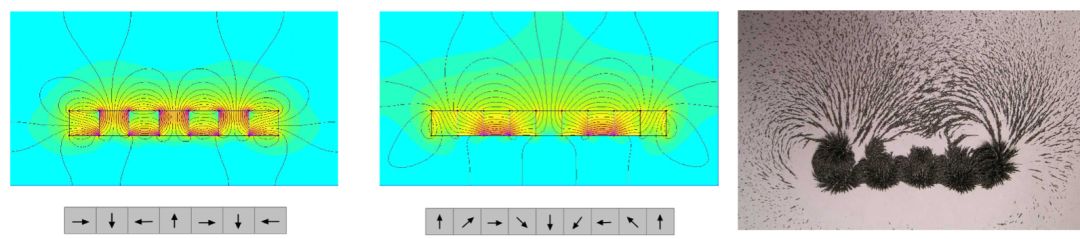

The linear type is the most basic form of Halbach array. This kind of array

magnet can be regarded as a combination of radial array and tangential

array, as shown in the figure below:

Linear Halbach arrays are currently mainly used in linear motors. The levitation

principle of the maglev train is that the moving magnet interacts with the magnetic

field generated by the induced current in the conductor to generate a levitation

force, accompanied by magnetic resistance. Increasing the buoyancy-to-resistance

ratio is the key to improving the performance of the levitation system. This

requires the on-board magnet to be light in weight, strong in magnetic field,

uniform in magnetic field, and high in reliability. The Halbach array is installed

horizontally in the center of the car body, and is produced by the interaction with

the winding in the center of the track.

Propulsion is generated, and the magnetic field is maximized with a small amount

of magnets, while the magnetic field on the other side is less, so that passengers

can avoid being exposed to strong magnetic fields.

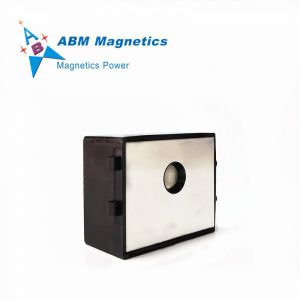

CIRCULAR ARRAY

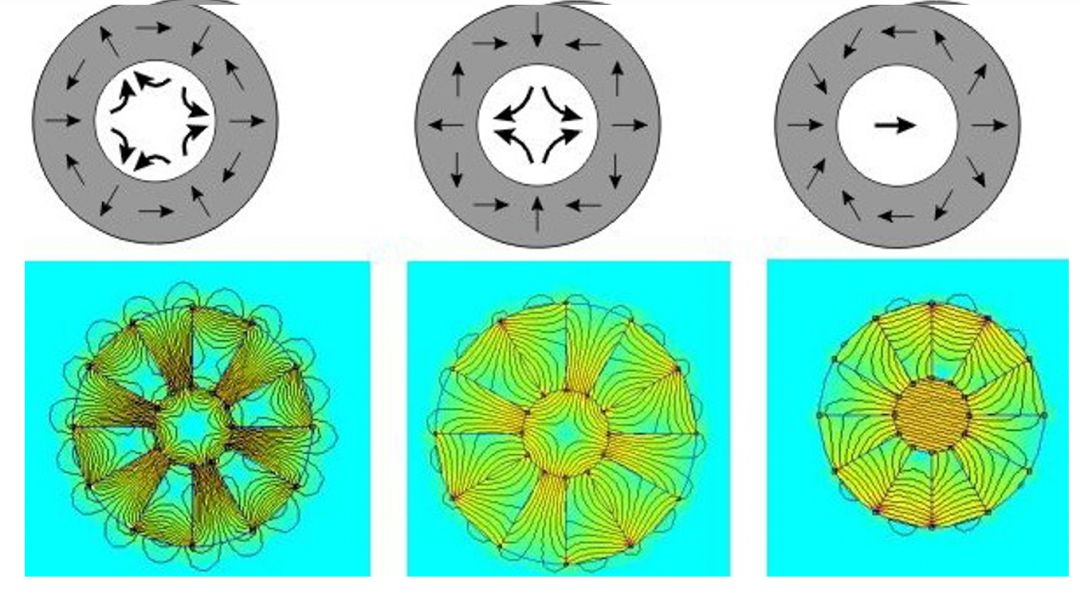

The circular Halbach array can be regarded as a ring shape formed by combining

the linear Halbach array end to end.

In the permanent magnet motor, the permanent magnet motor using the Halbach

array structure has a more sinusoidal air gap magnetic field than the traditional

permanent magnet motor. Under the condition of the same amount of permanent

magnet material, the air gap magnetic density of the Halbach permanent magnet

motor is higher and the iron loss is smaller. In addition, the Halbach ring array is also

widely used in permanent magnetic bearings, magnetic refrigeration equipment, and

magnetic resonance equipment.

THIRD,

Fabrication and production method of Halbach array

Method 1: According to the topological structure of the array, use magnetic steel

glue to bond the pre-magnetized magnetic steel segments together. Because the

mutual repulsion between the magnetic steel segments is very strong, it is necessary

to use a mold for clamping when bonding. The manufacturing efficiency of this

method is relatively low, but it is relatively easy to implement, and is more

suitable for use in the laboratory research stage.

Method 2: Firstly, a complete magnet is manufactured by mold filling or compression

molding, and then magnetized in a special fixture. The array structure processed

by this method is similar to the figure below. This method has high processing

efficiency and is relatively easy to achieve mass production. However, it is

necessary to specially design the magnetization fixture and formulate the

magnetization process.

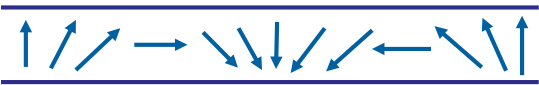

Method 3: Use a winding array of a specific shape to achieve a Halbach-type

magnetic field distribution, as shown in the figure below.