What is a magnetic coupling?

Magnetic couplings are known by professionals as magnetic drives and are widely used in a variety of general mechanical components.At present, magnetic couplings are used to connect two shafts, namely the motor shaft and the work shaft, and make them rotate together, eventually achieving the effect of transmitting torque.The magnetic coupling traditionally made must be connected with the driven shaft and the driven shaft to transmit torque. The structure of the magnetic coupling is very complicated, and the manufacturing precision is very high, otherwise it is easy to affect the production efficiency. In addition, the traditional magnetic coupling is also easy to overload when the failure of various components, especially easy to destroy the drive shaft and driven shaft between the sealing. When the drive shaft and the driven shaft work in two different media that need to be separated from each other, the sealing element must be used for sealing. If there is a problem with the sealing, harmful gas or liquid will be left in the system, once the leak will not only pollute the environment, but also endanger people's lives.

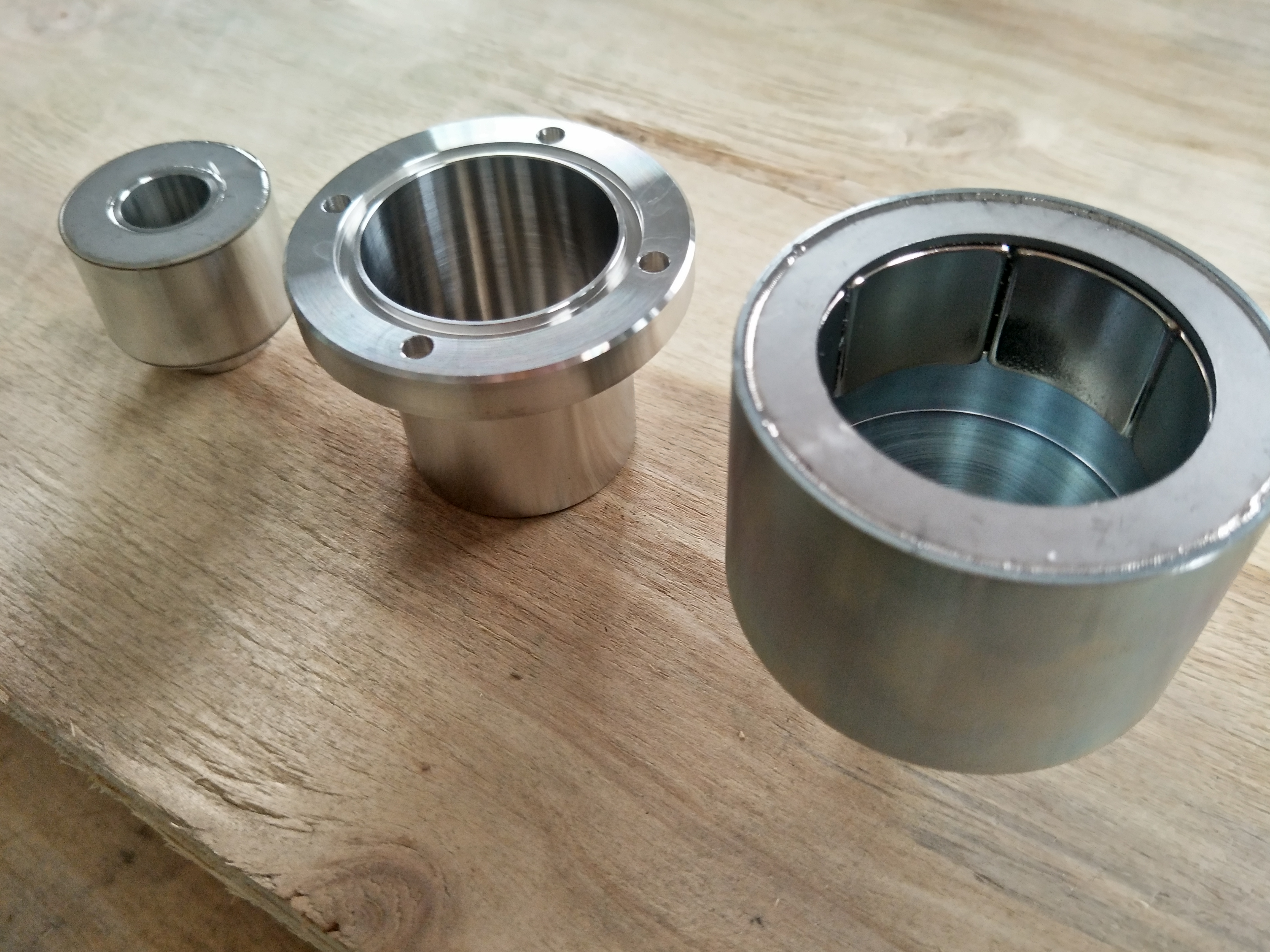

Magnetic coupling is a non-contact coupling, which is generally composed of two magnets, one of which is installed inside the system, the other is outside the system, and the two magnets are separated by the isolation cover in the middle. The internal magnet is connected with the driven part, and the external magnet is connected with the power part.Magnetic coupling in addition to have the function of the elastic coupling buffer vibration absorption, its biggest characteristic is that it broke the traditional magnetic coupling structure, using new magnetic transmission principle, implementation not by direct contact between driving shaft and driven shaft can force and torque transmission, and the dynamic seal into static seal, zero leakage. Therefore, it is widely used in the special requirements of leakage occasions.

相关资讯

- What are the common coatings of sintered NdFeB Magnet ?

- Mould pressed bonded neodymium iron boron magnet will become the most practical and affordable "

- Application of ndfeb magnet in NMR imager

- What is a magnetic coupling?

- 钕铁硼磁铁在汽车微特电机的应用

- 粘结钕铁硼磁铁应用到永磁步进电动机上,效果太赞!

- 粘结钕铁硼磁铁的防潮、抗氧化问题如何解决?

- 为什么强力磁铁只能吸铁跟铜的?

- 沉头孔钕铁硼磁铁和圆环钕铁硼磁铁的生产与注意事项

- 强力磁铁做盐雾试验的作用以及相关概念