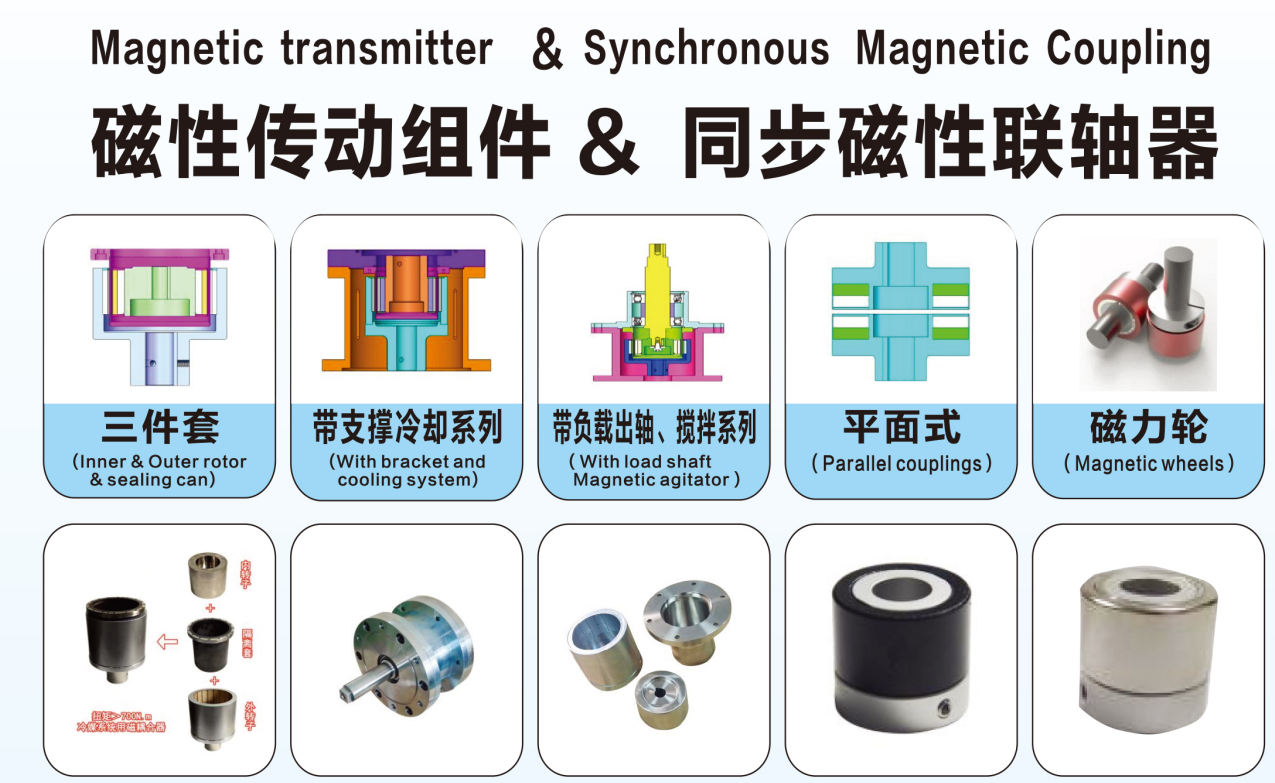

Magnetic Coupling

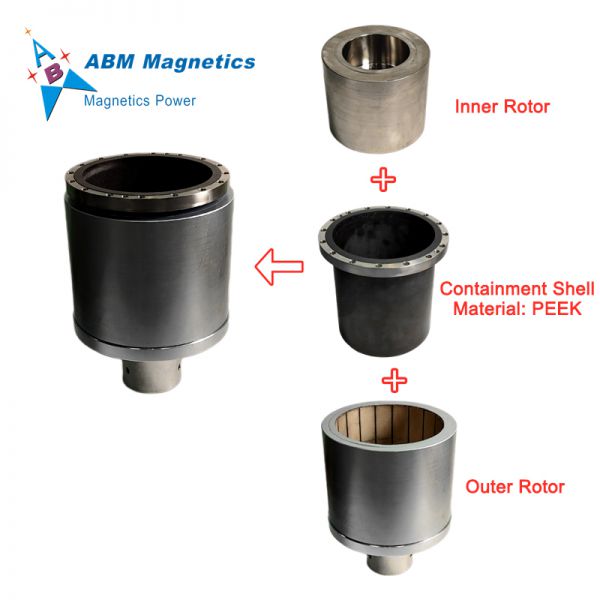

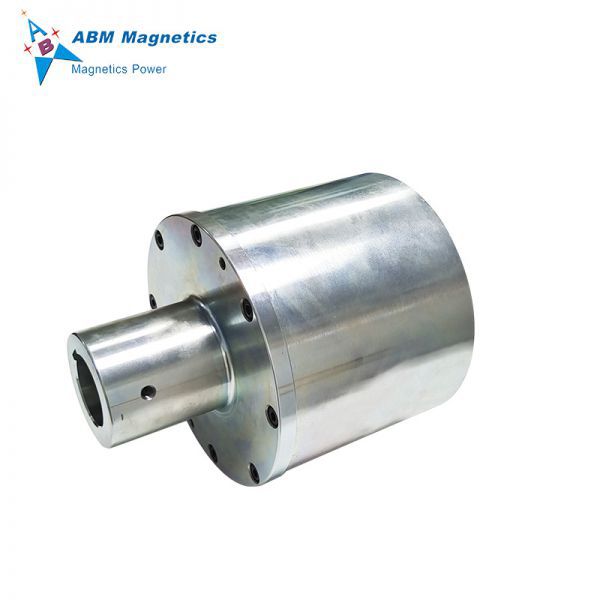

Magnetic transmission coupling: generally composed of two inner and outer magnets, the two magnets are separated by an isolation cover in the middle, the inner magnet is connected to the driven part, and the outer magnet is connected to the power part.

订制热线:0755 - 25989963

产品信息

ABM Magnetics Supply:

Magnetic Coupling/Permanent Magnetic Coupler/

Magnetic Damper

FIRST,

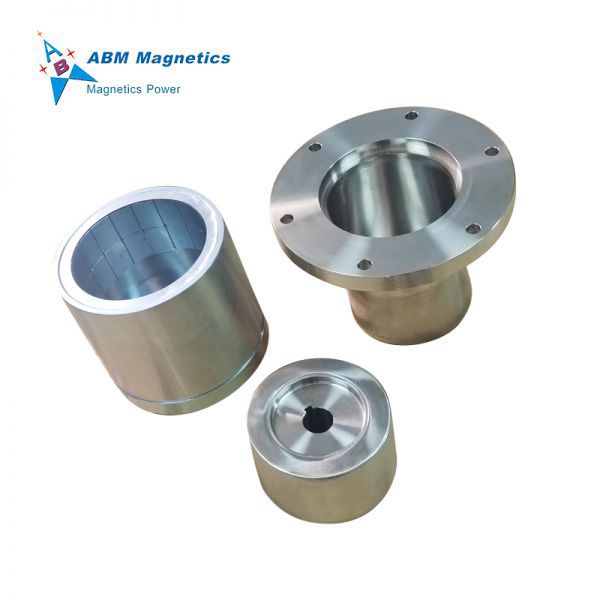

The permanent magnet coupling is mainly composed of

three parts: inner rotor spacer sleeve outer rotor

INNER ROTOR:

Generally, it is made of SS304, and the liquid-contacting parts are all made of

stainless steel, and the sealing test is performed by light welding. In order to

improve anti-corrosion performance and prolong product life.

SEALING CAN:

304, 316/316L, PEEK, titanium alloy, Hastelloy alloy

OUTER ROTOR:

The magnetic steel is electroplated with NI treatment, and the exterior is painted.

Generally, it is made of Q235 material to achieve the purpose of magnetic

isolation.

SECOND,

The Sealing can is the most critical component of the permanent magnet coupling.

The use of the permanent magnet coupling will inevitably cause eddy current

heating of the Sealing can. The quality of the Sealing can is the key to

determining whether the static seal of the customer can be achieved.

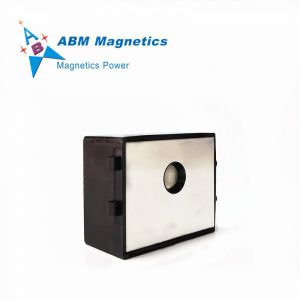

PEEK:

It is recommended to use this material when the speed is high, the pressure is

relatively low, the maximum is 3 Mpa, and it does not generate heat;

SS304/316:

Under high pressure, high-speed operation will generate eddy current heating; This

problem can be solved by return flow cooling.

Titanium alloy, Hastelloy alloy: one-piece processing, withstand high pressure.

THIRD,

Comparison of advantages and disadvantages of magnetic

coupling:

| ITEM | Advantages Of Magnetic Couplings ---Contactless Power Transmission | Disadvantages Of Transmission Contact Transmission |

| 1 | Static Seal For Zero Leakage | Cannot Be Statically Sealed |

| 2 | No Noise, Shock Absorption | Noisy |

| 3 | Synchronous Transmission, 100% Efficiency | Start Out Of Sync |

| 4 | Simple Structure And Easy Maintenance | Need Regular Maintenance |

| 5 | Soft Start, Overload Protection | Wear Affects Accuracy |

| 6 | Millimeter Alignment | |

| 7 | Starting Angle Small | |

| 8 | The Max Torque Can Reach 5000N.M | |

| 9 | Low Production Cost |

FOURTH,

Structural selection of magnetic coupling:

Choose the coupling that suits you:

FIFTH,

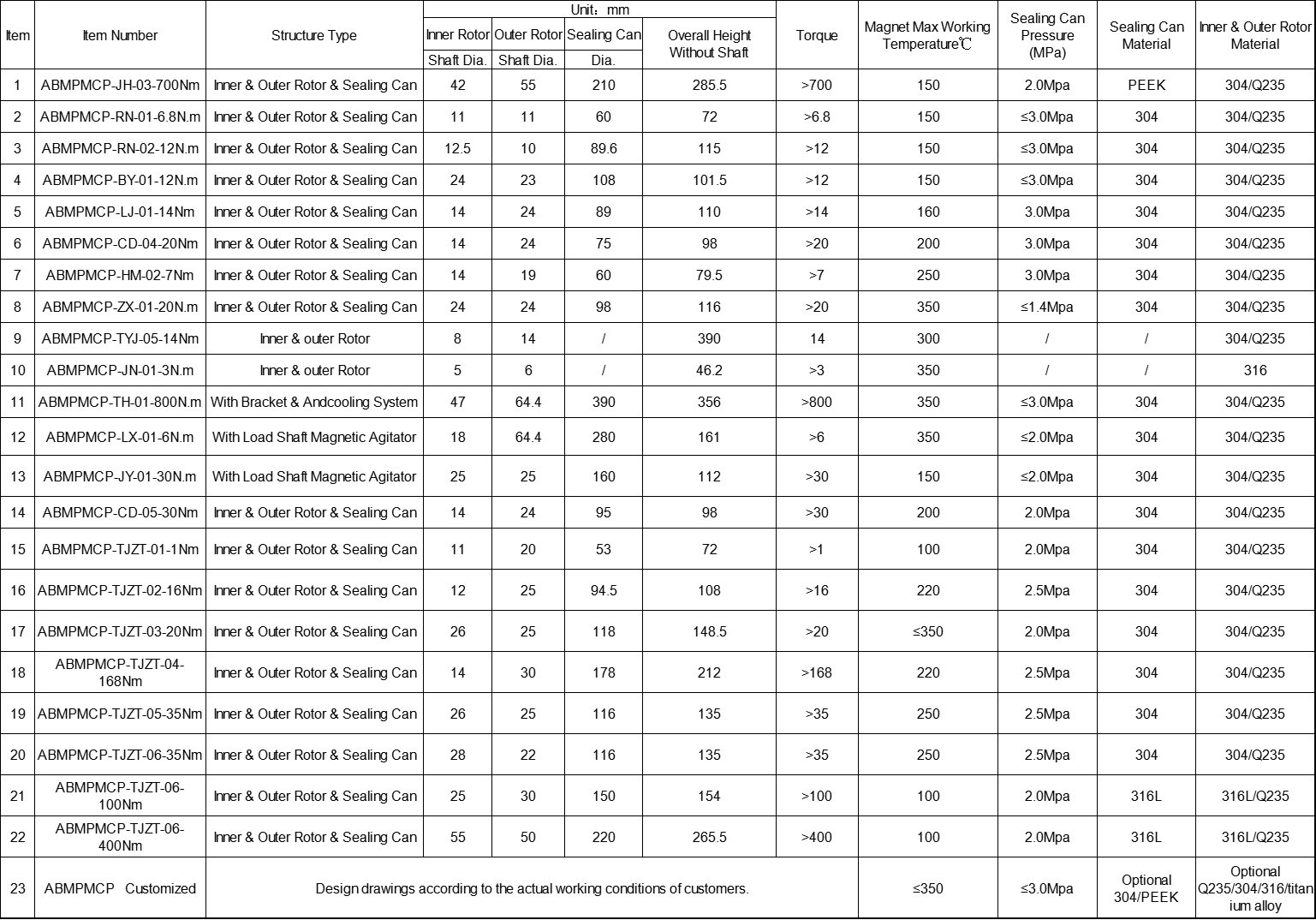

Magnetic coupling dimension table:

Please see the PDF file below for details.

SIXTH,

Inquiry information provided:

1. Let us know what the coupling does, Please. Shock absorbing or sealing?

2. Motor power;

3. Motor speed (is there a reducer?);

4. Required torque;

5. Medium and working temperature;

6. Working pressure;

7. Whether it is anti-corrosion;

8. Corrosion requirements;

9. Is there any size design requirement?

10. Quantity;

SEVENTH,

Processing and testing equipment:

EIGHTH,

Reference knowledge points for the selection of magnetic

couplings:

1. The temperature of the medium: when <120°C, use NdFeB magnets, and

when >120°C, use samarium cobalt magnets.

2. The corrosiveness of the medium: when the medium is corrosive, 316

should be used as the magnet matrix, and when the medium is non-corrosive,

304 should be used as the magnet matrix.

3. Medium viscosity: When the medium viscosity is too high, the torque of

the magnetic coupling should be increased accordingly to ensure the smooth

operation of the transmission.

4. Working pressure: If the pressure is too high, the wall thickness of the

isolation sleeve should be increased accordingly.

5. Power and speed: The torque of the magnetic coupling is determined by

the power and speed, so that the coupling of the corresponding

specification is selected for use.

6. It can also be customized and processed according to customer requirements.

NINTH,

Troubleshooting points for magnetic couplings:

1. Outer rotor and inner rotor are not synchronous, and the slippage is serious,

because the torque of the magnetic coupling is too small.

Solution: Replace the high-torque magnetic coupling.

2. The inner rotor does not rotate:

The driven shaft is stuck or solidified by the medium;

The inner rotor is demagnetized.

Solution: remove foreign matter, or melt the medium to make it run

normally, if the inner rotor is demagnetized, it needs to be replaced.

3. Demagnetization of the inner rotor: First, it is caused by the high

temperature of the medium and improper selection of magnetic materials;

second, it is because the inner rotor and the outer rotor are out of sync and

slips seriously, and the inner and outer rotors generate heat under the

action of magnetic coupling. If the heat dissipation is not smooth and the

temperature is too high, the inner rotor will be demagnetized.

Solution:

Select high temperature magnet;

Replace high torque magnetic coupling